Swing gate valves

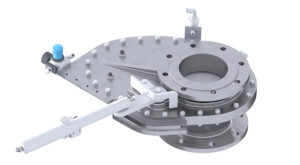

Standard KU-STD

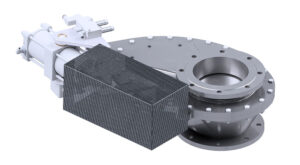

High temperature swing gate valve KU-HT

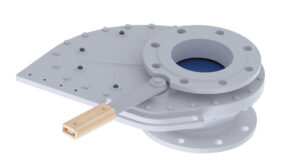

Pressure-/vakuum swing gate valve KU-HP-PAM

The particular advantages:

____________________

- Extremely short opening and closing time (< 1 sec)

- Completely encapsulated housing

- Absolutely material, gas- and pressure-tight to the atmosphere

- Shutting off flowing material

- Also suitable for difficult bulk materials

- Large variance in configuration and construction

- For almost all areas of application

Profit from our expertise!

We offer you:

- Free and non-binding consultation

- Objective and individual advice

- Holistic support in all phases of your projects

- Guaranteed suitable product solutions

Get in contact with us!

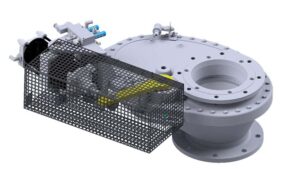

Swing gate valves

Due to their particularly effective design, Schütte swing gate valves offer clear advantages over other bulk material valves and are used wherever the highest demands are placed on process safety.

The swing gate valve KU-HP+PAM with its unique inflatable “Press-Airmatic®” inlet seal is additionally pressure- and vacuum-tight in the passage. The swing gate valve KU-HT is also suitable for high-temperature bulk materials.

All swing gate valves are easy to handle and are characterised by their long service life, especially in applications with high operating intervals.

CONSTRUCTION & FUNCTION

The swinging movement of the swing gate installed in the housing leads the flow of material and guides the bulk material past the round swing gate into the volume of the lower part of the housing. In this way, an optimal displacement of the material can be achieved with little effort.

The adapted seals prevent possible jamming or clogging during the closing process and ensure safe shut-off even of difficult bulk materials such as dust or sharp-edged media.

Built-in air and water flushes can remove serious deposits from the inner walls of the fitting and prevent process-critical malfunctions and failures.

INDIVIDUALLY ADJUSTABLE

The right choice of material, which is individually adapted to the bulk material, reduces abrasion and wear on the valve’s components that come into contact with the medium and ensures an above-average service life overall.

The swing gate valve can be equipped with various actuations and, in addition to the appropriate selection of nominal dimensions and cross-section, they can also be customized for any installation situation by adding specific adapters.

Due to the wide range of configuration options, the swing gate valve suited to cover the most demanding task assignments All swing gate valves are easy to handle and can be used with high switching frequencies.

The SCHÜTTE swing gate valves have already proven themselves with almost all bulk materials and in many difficult areas of application.

The particular advantages:

____________________

- Extremely short opening and closing time (< 1 sec)

- Completely encapsulated housing

- Absolutely material, gas- and pressure-tight to the atmosphere

- shutting off flowing material

- Also suitable for difficult bulk materials

- Large variance in configuration and construction

- For almost all areas of application

Profit from our expertise!

We offer you:

- Free and non-binding consultation

- Objective and individual advice

- Holistic support in all phases of your projects

- Guaranteed suitable product solutions

Get in contact with us!

Actuation/ Drive

- Hand lever

- Electro-pneumatic

- Electro-pneumatic with positioner

- Electro-motoric

- Hydraulic

Options

- Intermediate positions for metering

- Ex-protection of cylinder, solenoid valve

Limit switch and junction box - Non-stick coatings

- Special flanges

- ATEX certificates on request

Applications

- Emergency shut-off

- Silo shut off

- bunker discharge

- Metering

- Partial shut-off

- Process valve

- Sealing valve

Technical data and materials

| NOMINAL SIZE | DN 80 – DN 500 (4″ bis 20″) |

| FLANGE | DIN or ANSI |

| HOUSING | Cast steel, stainless steel or aluminium To the materials =>> |

| GATE/DISC | Stainless steel To the materials =>> |

| SEAL | Plastic plastics, elastomers, metallic To the materials =>> |

Technical data without guarantee. Customised design (voltage, power, speed, protection class, etc.) can be implemented.

APPLICATION AREAS

- Food industry

- Feed industry

- Pharma industry

- Plastics industry

- Building materials industry

- CHP plants

- Waste incineration plants

- Process technology and plant construction

Additional versions

|

>> Swing Gate Valve KU-Standard |

|

>> High-Temperature Swing Gate Valve KU-HT |

|

>> Pressure-/Vacuum Swing Gate Valve KU-HP+PAM |