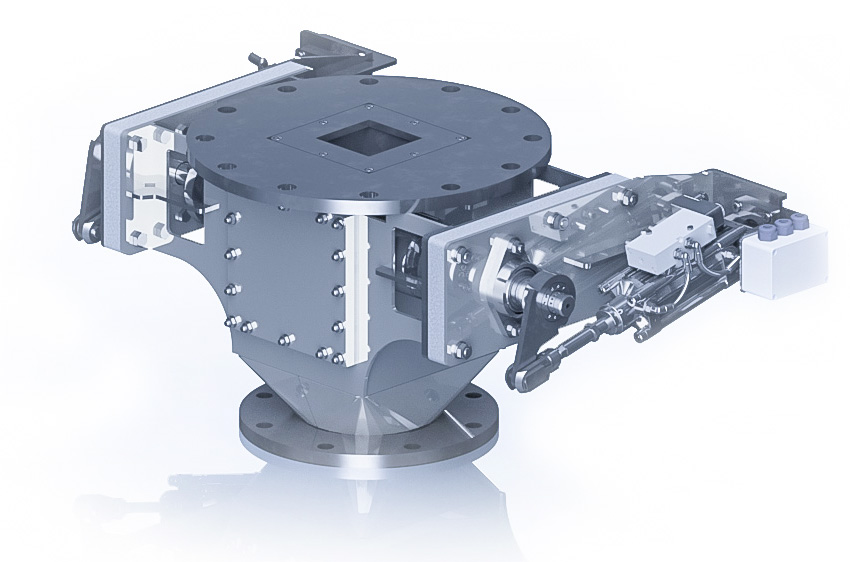

Segment valve

SGM 100 HT

The particular advantages:

____________________

- Short closing and opening times (< 1 sec)

- Completely encapsulated housing

- Material, gas- pressure tight to the atmosphere

- Shutting off flowing material

- Also suitable for difficult bulk materials, e.g. ceramic balls

- For almost all areas of application

- High temperature range

up to 1000 °C

Segment valve SGM 100 HT

The segment gate valve is a special design of a gate valve, which has been adapted in its construction and function to the requirements of the operational work process. The peculiarity of this design is the shut-off mechanism. Regular gate valves, such as the flat slide or swing gate valves, close the passage using a horizontally moving gate blade. This interrupts the flow of material. ( -> Swing gate valve) The double flap valve rotates the closing flap and thus interrupts the material flow.

This new function offers a further development of the closing flap. In form of an asymmetrically rotating blade, this enables a closing process that is particularly optimized for abrasive bulk materials. Abrasion and wear on the material can thus be significantly reduced.

The segment gate valve with stainless steel housing is equipped with a hydraulic drive on both sides and can also be used for high-temperature bulk materials up to 1000°C with appropriately adapted material parts. The segment gate is gas-tight on the outside and material-tight in the passage.

Another advantage of this design is the breaking of flowing columns of material.

Actuation/ Drive

- Electro-pneumatic

- Electro-motoric

- Hydraulic

Options

- Drive explosion protection

- Magnetic valve

- Limit switch and terminal box

Applications

- Emergency shut-off

- Silo shut off

- Bunker discharge

- Metering

- Partial shut-off

- Process valve

- Sealing valve

Technical data

| SIZES | 100 x 100 mm funnel, others on request |

| HOUSING | Steel, stainless steel welded structure To the materials => |

| SHOVEL | Stainless steel To the materials => |

| SEAL | Plastics, Elastomere, Metallic To the materials => |

Technical data without guarantee. Customised design (voltage, power, speed, protection class, etc.) can be implemented.

Application areas

- Food industry

- Feed industry

- Pharma industry

- Plastics industry

- Building materials industry

- CHP plants

- Waste incineration plants

- Process technology and plant construction

- Plants with ceramic heat carriers