Flat slide valves

ZFT

ZFB

ZFB Standard

Pressure-/vacuum slide valve ZFB+PAM

Flat slide valves in welded construction

VEG Standard

Pressure-/vacuum slide valve GAS+PAM

We would be pleased to give you advice

____________________

on the solution that fits your requirements the best.

We will help you to determine the right components for you with a few parameter specifications.

Get in touch with us!

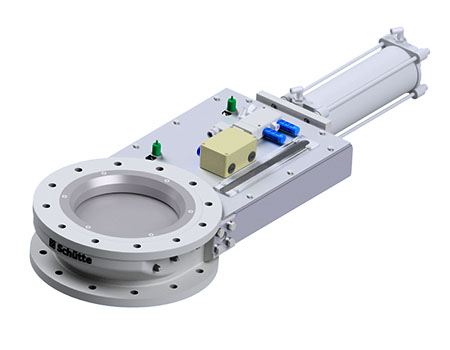

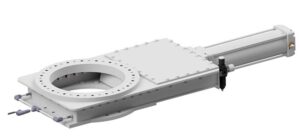

Flat Slide Valve ZFB Standard

The flat slide valve ZFB Standard is dust-tight in the passage and gas-tight to the atmosphere.

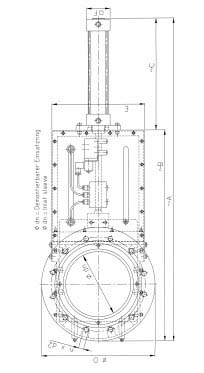

DESIGN AND CONSTRUCTION

The flat slide gate valve ZFB Standard has a well-designed cast housing. Despite the low height, the housing has very steep discharge walls in the lower part. In vertical installation position, it can prevent the process-critical product deposits in the gate valve housing.

A large separation space in the front area ensures a better flow of material and also enables the closing against standing material columns. This favours the flow of material during the closing process and thus also enables shut-off in standing material columns.

FLANGE

The flat slide valve ZFB Standard has round flanges according to EN1092 and ANSI B16.5 and can be supplied in nominal sizes from DN100 up to DN600 (EN) or NW4″ up to NW24″ (ANSI).

SEALING

The housing of the flat slide valve ZFB is not encapsulated. At the passage to the slides head, the slides blade is sealed by a stuffing box. The valve gate is sealed at the passage to the valve head by an adjustable packing gland. The back space has no seals; it mainly protects against the moving components and embeds necessary control and regulation technology.

The overhead seal wipes off the bulk material during the closing process and seals the slide gate valve with a maximum of dust-tightness.

CONFIGURATION

The pressure-/vacuum gate valves ZFB+PAM with the “Press-Airmatic®” seal are also gas-, vacuum- and pressure-tight in the passage.

Due to the modular design, it is possible to adapt each component of our ZFB flat slide individually to your operational requirements. Our wide range of material covers a broad spectrum of regulations from the food and chemical industries. You can choose between manual and automatic actuations. If the bulk material has a strong tendency to ahesions, our ZFB flat slide valves can be additionally equipped with an air or water flushing system.

SPECIAL DESIGN

Optionally, our ZFB flat slide valves can also be designed for the high temperature range and/or ATEX-compliant.

Product-advantages

- Large separation space in the front area allows the gate to close against the standing material columns without jamming.

- Short opening and closing intervals (< 2 sec.)

- Dust-tight in the passage, gas-tight to the atmosphere

- Low height

- Low maintanance

- As an operation valve even at high switching frequencys

- Overhead wiper seal

- ATEX-compliant version optional, as per specified requirement

- Available in sizes up to DN 600 (DIN)

- Wide choice of materials (steel, stainless steel or cast aluminium)

We would be pleased to give you advice

____________________

on the solution that fits your requirements the best.

We will help you to determine the right components for you with a few parameter specifications.

Get in touch with us!

Actuation/ Drive

- Hand wheel, crank

- Chain wheel

- Electro-pneumatic

- Electro-pneumatic with positioner

- Electro-motoric

Options

- Intermediate positions for metering

- Explosion protection of actuator, solenoid valve, limit switch and terminal box

- Non-stick coatings

- Special flanges

- ATEX certificates on request

Technical data

| NOMINAL SIZE | DN 100 – DN 600 (4″ bis 26″) |

| FLANGE | DIN PN6/ PN10 oder ANSI 150 Lbs, oder auf Anfrage |

| HOUSING | Cast steel, stainless steel or aluminium To the materials =>> |

| GATE/DISC | Stainless steel To the materials =>> |

| SEAL | Plastics, Elastomere, Metallic To the materials =>> |

Technical data without guarantee. Customised design (voltage, power, speed, protection class, etc.) can be implemented.

Additional versions

|

>> Knife gate valve ZFT |

|

>> Welded construction slide valve |