Big Bag-Emptying stations

Above all, Big Bag emptying systems have to be reliable, effective and economically efficient. The emtying stations from Schütte Industrieservice are based on a modular design, the technology of which can be individually adapted to the respective product-specific bulk material properties.

This offers you maximum flexibility in configuration, even for critical or problematic material discharges – such as clumping, caking or hazardous or moist media.

We distinguish between the following basic variants, which can be supplemented by corresponding process extensions and thus guarantee you optimum emptying performance.

PROFIT FROM OUR EXPERIENCE:

____________________

- 50 years of experience in bulk solids technology

- Proven cross-industry concepts

- Satisfied customers worldwide

- Quality Made in Germany

Basic variants:

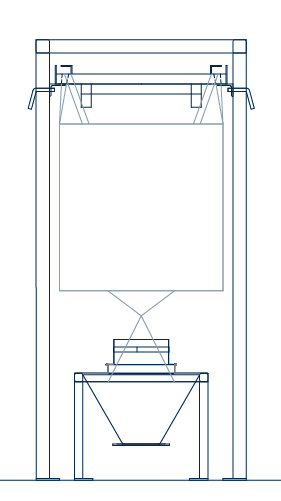

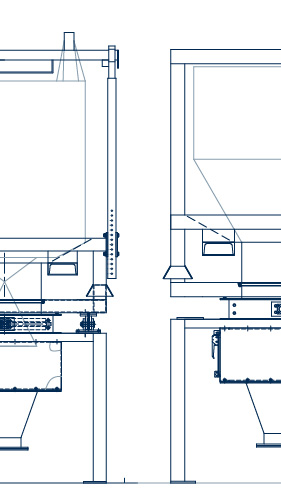

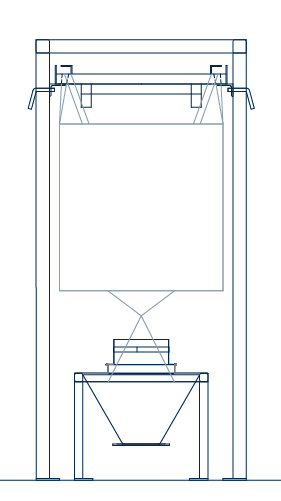

Type 1 BASIC

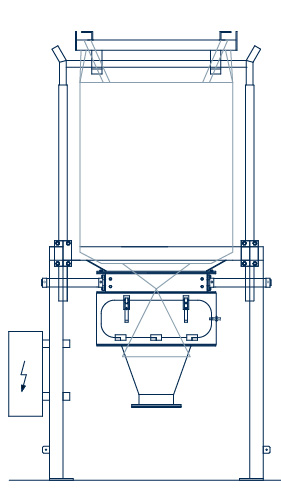

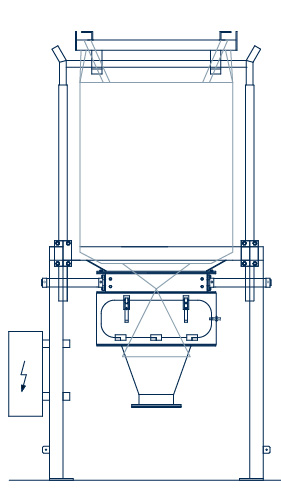

Type 2 Norm

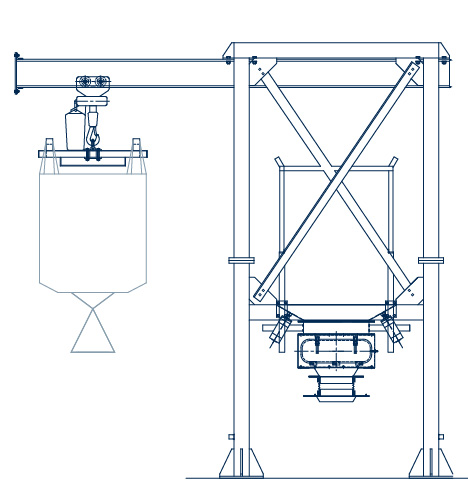

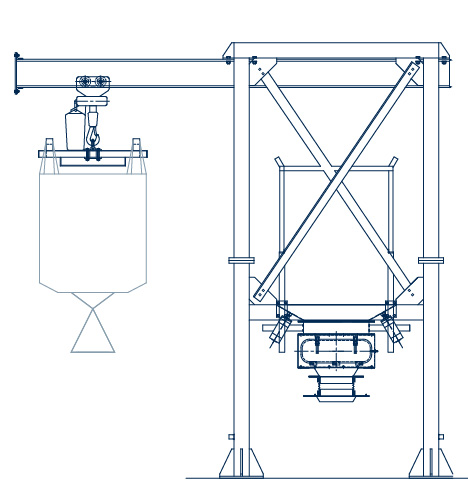

Type 3 Crane

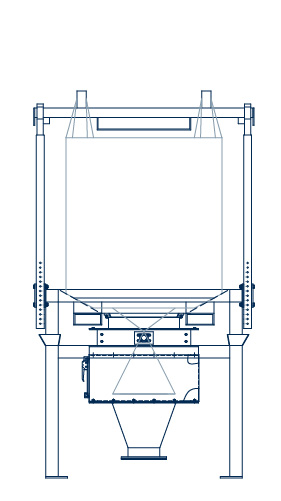

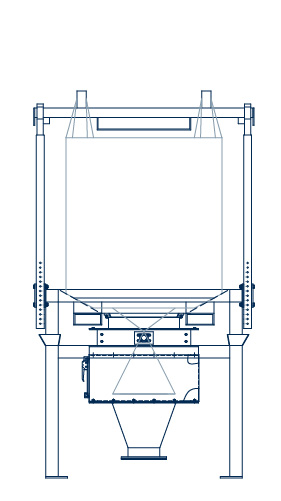

Type 4 Low Height

Type 5 Multi

Our emptying stations are easy to install and offer equally easy and safe handling.

Depending on the basic variant, the following extensions can be configured:

Weighing

Disposable Big Bags

Pneumatic massage

Vibration-

floor

Big Bag crescent-shaped closure

Sack feed

Dust-free clamp closure

Product extraction aids

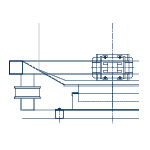

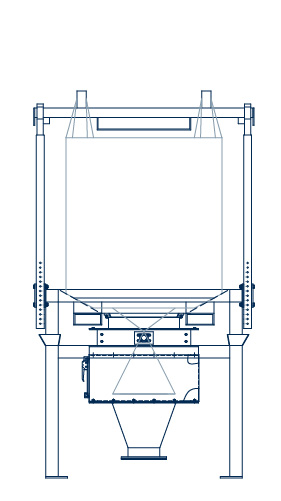

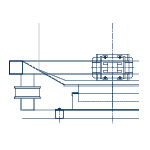

Type 1 BASIC

Basic equipment:

The basic emptying station is ideal for the use with free-flowing or granular, dust-free and environmentally-friendly bulk materials.

- Base frame with mechanical height adjustment, to adopt to different Big Bag sizes

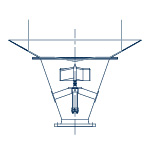

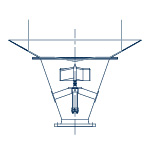

- Big Bag lifting cross

- Emptying hopper with top-side clamping device; below this unit we are pleased to offer to you the installation of further mechanical or pneumatic discharge devices, e.g. screw conveyors, rotary feeders, blowers etc.

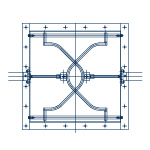

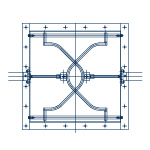

Type 2 NORM

Basic equipment:

The emptying station Type 2 – NORM can be employed for all types bulk materials – whether granular or fine-grained, free-flowing or poorly flowing, environmentally friendly or harmful to the environment.

- Base frame with the Big Bag settling platform, sealed off with a surrounding soft seal

- Lateral and spring pretensioned holder arms for stretching the Big Bag as it is emptying; incl. a mechanical height adjustment for easy adoption to different Bag sizes

- Big Bag lifting cross for positioning the Big Bag on the holder arms

- Action box to ensure dust-free transfer of the bulk material from the Big Bag into the system; incl. discharge neck nozzle and mechanical clamping device and a lateral aspiration nozzle

- Emptying hopper; incl. a lateral nozzle for connection of level sensors

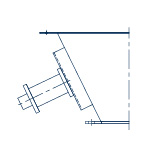

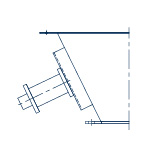

Type 3 Crane

Basic equipment:

Whenever Big Bags are to be processed without the use of fork-lifts or other lifting devices our emptying station Type 3 – CRANE is ideally suited to cover the task.

The base frame is fitted with a crane and a beam hoist, so that the Big Bag can be raised with the lifting cross and passed into the station. Execution of steel works and crane installation always primarily adopt to Big Bags to be processed, but we are pleased to take account for your individual requirements.

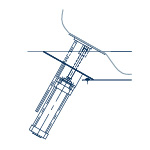

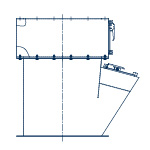

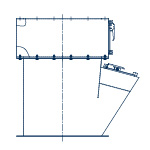

Type 4 Low Height

Basic equipment:

With limited space, especially with constricted usable headroom and limited reach of fork lifts, our Big Bag emptying station Type 4 – LOW HEIGHT can still easily be employed.

The Big Bag to be unloaded is rested inside a detachable loading frame which is then placed on top of the low-height base frame of the station. Only this setup enables the processing of Big Bags under constricted height conditions.

Type 5 Multi

Basic equipment:

If an achievement of maximal variability is your objective and both Big Bags and containers are to be emptied on one single station, our Big Bag emptying station Type 5 – MULTI is ideally suited for this task.

On the basis of the design for the emptying station Type 4 – LOW HEIGHT and the measurements of the containers to be processed, we supply the right solution to you!

Add-ons:

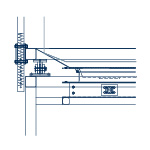

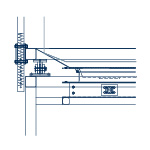

Weighing

To determining the quantities removed from the Big Bag or for the metered discharge we are pleased to offer to you the following solutions:

Decoupling of the Big Bag settling platform and further equipment with 3-4 load cells incl. an analysis unit. With further signal processing to a SPS control system or an optional printer the discharged quantities can be safely measured. In connection with our auxiliary module Crescent-shaped Big Bag closure and a downstream conveyor unit, it is further enabled to selectively control the quantities discharged from the Big Bag.

Disposable Big Bags

To enable the processing of disposable Big Bags we offer to you a practical and reliable slitting device. It cuts the Big Bag from below, allowing the controlled discharge of the bulk material. Afterwards the Big Bag is being disposed.

Pneumatic massage

To assist the product flow with critical and bridge building bulk materials, we offer to you our pneumatically-operated massage systems.

For implementation, pneumatic actuators, fitted with frontal pressure plates are installed at the stations base frame. These massage the Big Bag lateral and/or from below and thus assist the product flow.

Vibrating floor plate

The vibration floor plate is used in combination with bulk materials that do not flow from the Big Bag without assistance, but which can be transferred to a free-flowing state by vibrating the Big Bag settling platform.

Big Bag crescent-shaped closure

The crescent-shaped closure ties up the discharge neck of the Big Bag any time when required, thus enabling partially-emptied Big Bags to be resealed – also able to be employed together with the weighed discharge of Big Bags.

Sack feed

Whenever aggregates have to be added to the production process, a sack feeding device is being employed, which can be integrated into the stations emptying hopper.

The filling opening of the sack feed is executed with dust-tight seals and monitored by a limit switch.

Dust-free clamp closure

The clamp closure ensures the dust-free, secure pressing of the Big Bag discharge neck onto the emptying tube within the action box.

This ensures that the Big Bag discharge neck is fully opened with a dust-free seal to the outlet, enabling the product to flow unhindered from the Big Bag.

Product extraction aids

When working with critical products the stations emptying hopper can be equipped with further fluidisation devices or pneumatic tappers, which support the product discharge and prevent bridging within the outflow cone.

Projects