Double Flap Valves

DFG-SH

DFG-FH

Double Cone Valve DFG-ST

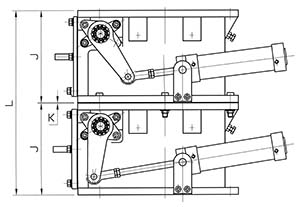

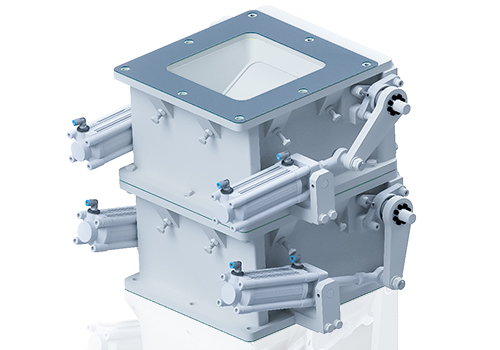

Double Flap Valve DFG-SH

The double flap gate valve dfg-sh is for the safe, continuous infeed and discharge of dry, free-flowing bulk materials from and into pressure differential spaces, such as filter separators, clinker plants, rotary kilns etc.

Product-advantages

- Low overall height, exchange for rotary valve possible

- Gas-tight to the atmosphere, material-tight in the passageway

- Simple operation monitoring, without removing the valve

- Easy replacement of spare parts in installed condition

- Long service life

Actuation/ Drive

- Weight-loaded

- Electro-pneumatic

- Electro-motoric

- Hydraulic

Options

- Explosion protection of actuator, solenoid valve, limit switch and junction box

- Non-stick coatings

- Pressure-tight design according to DGRL AD2000 for the introduction of electrostatic precipitator ash into a pneumatic filter promotion

- ATEX certificates on request

Technical data

| SIZES | 200 x 200 – 400 x 400 or on request |

| HOUSING | Cast steel, stainless steel or aluminium To the materials =>> |

| FLAPPER | Stainless steel To the materials =>> |

| SEAL | Plastics, Elastomere, Metallic To the materials =>> |

Technical data without guarantee. Customised design (voltage, power, speed, protection class, etc.) can be implemented.

Projects

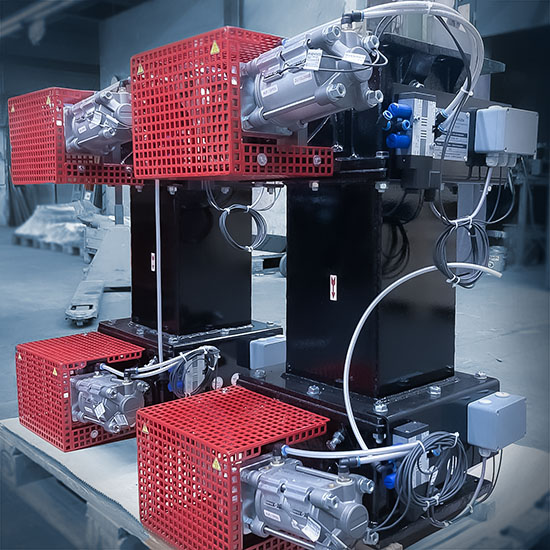

Double flap valve DFG-SH in special height

and corrosion-protective surface coating. The intermediate piece with a height of 200 mm installed between the two flap gates has a positive effect on the flow characteristics of the bulk material and the resulting separation process. The electric-pneumatic drive has been further reduced in size and is therefore even more space-saving and less vulnerable to external influences. The interval switching is carried out via an on-site control system.

Additional versions

|

>> Double flap valve DFG-FH |